|

| | | | | | |

ENG: SITRANS TS temperature sensors

ENG: SITRANS TS temperature sensors

SITRANS TS100 7MC711xx

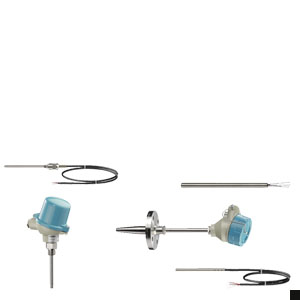

The following image illustrates the available designs for SITRANS TS100 temperature sensors:

SITRANS TS100 cable temperature sensor, sensor, plastic-sheathed cable design (MIC)

The following types of process connections can be implemented:

- Compression joint

- Spring-mounted compression joint

- Soldering nipple

- Direct soldering/welding in

SITRANS TS200 7MC712xx

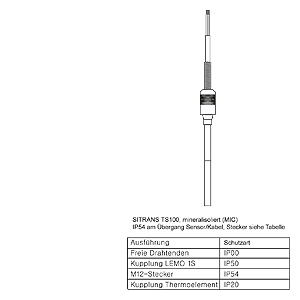

The following image illustrates the available designs for SITRANS TS200 temperature sensors:

SITRANS TS basic sensor

The following types of process connections can be implemented:

- Compression joint

- Spring-mounted compression joint

- Soldering nipple

- Direct soldering/welding in

SITRANS TS500 7MC75xx

The following image illustrates the available designs for SITRANS TS500 temperature sensors:

SITRANS TS500

The temperature sensors of the SITRANS TS500 series are available in three different designs:

|

Version

|

Description

|

Application

|

Process connection

|

|

1

|

- Protective sleeve made of pipe material

- Protective sleeve and extension made of one pipe;

- closed off with a welded bottom cap at the tipgrn

|

Minimal to medium process requirements

|

- Connected with thread or flange

- Thread is welded on, or compression joint

|

|

2

|

- Protective sleeve made of solid material

- Protective sleeve made of solid material, extension made of piping material; extension screwed into protective sleeve

|

Medium to highest process requirements

|

- Directly welded into pipeline

- With welded flange

- With male thread

|

|

3

|

- For installation into existing protective sleeves.

- Extension made of piping material

|

Process requirements dependent on protective sleeve design

|

Screwed into existing protective sleeve.

|

|